A high-performance and sustainable refrigeration solution for a food warehouse

In Longueuil, AirGreen recently completed the installation of a Bally commercial refrigeration system for an industrial cold storage facility used for storing perishable goods. Our client—a regional food distributor—aimed to modernize its refrigerated infrastructure to meet industry standards for performance, food safety, and energy efficiency.

Project context

The intervention site included several refrigerated storage areas dating back more than 15 years.

The existing system featured:

-

significant heat loss due to aging insulation,

-

an unstable indoor temperature , fluctuating between 2°C and 8°C,

-

and excessive electricity consumption .

The client commissioned AirGreen to design and install a new, complete system , including:

-

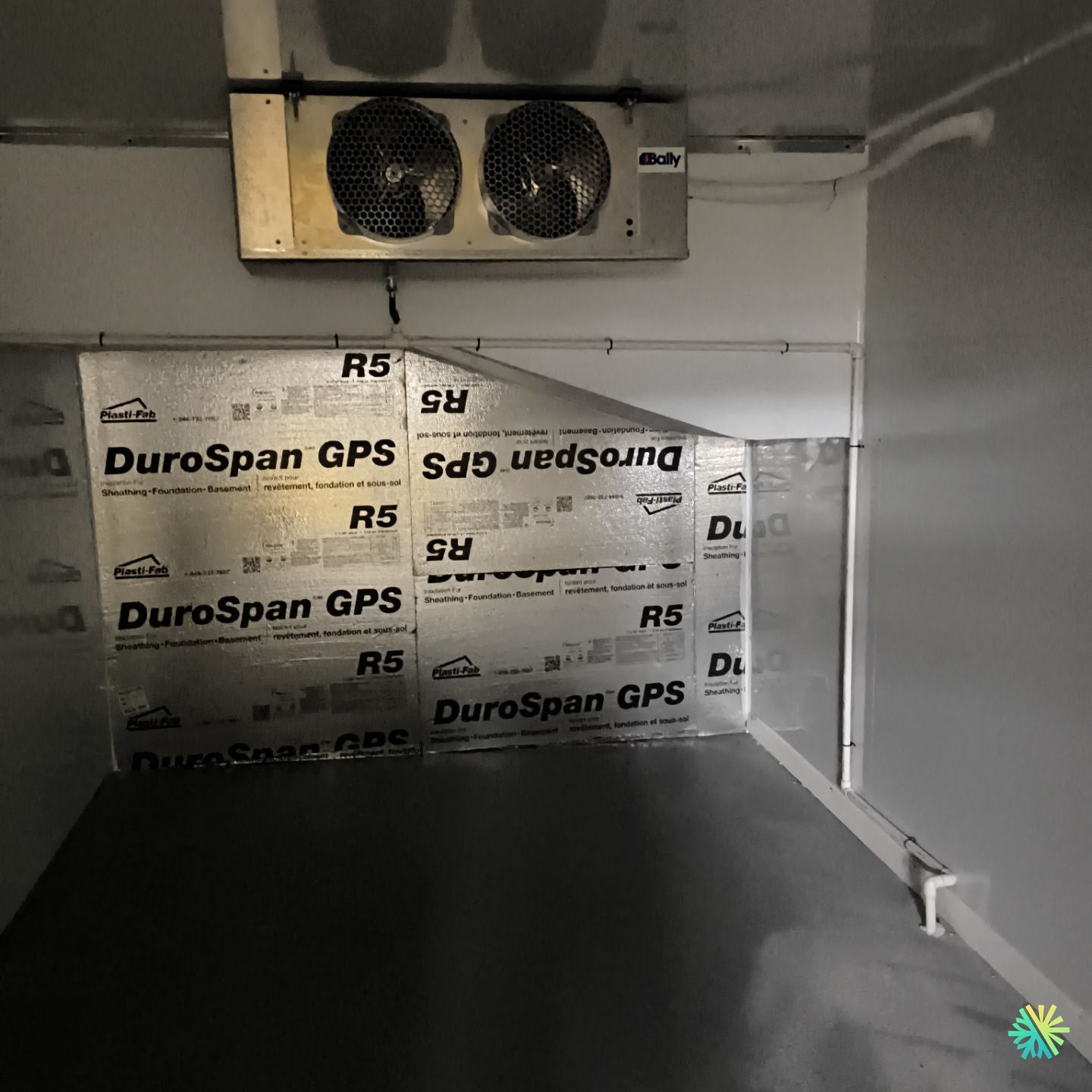

the Bally evaporation unit,

-

improved wall insulation (DuroSpan GPS R5),

-

and the upgrading of the drainage and refrigeration cabling network.

Technical constraints

This project required meticulous coordination because:

-

the need to keep the other refrigerated areas operational during the works,

-

limited space for installing refrigeration lines and evaporators,

-

and compliance with HACCP and MAPAQ standards regarding hygiene and food safety.

The work was planned to minimize any disruption to the cold chain . All stages were carried out under controlled temperature conditions and continuous technical supervision.

Preliminary diagnosis and studies

Before beginning the installation, our engineers carried out the following:

-

temperature and relative humidity measurements at different points in the cold room,

-

a leak test to assess air leakage,

-

and thermal modeling using load data in kW and air volume.

The results made it possible to identify the weak points of the insulating envelope and to precisely calibrate the sizing of the Bally system .

Technical solution implemented

The AirGreen team selected a high-efficiency Bally dual-fan evaporation system , coupled with a remote variable-speed condenser , to ensure:

-

a homogeneous distribution of cold air ,

-

precise temperature control between 1°C and 3°C,

-

and a reduction in noise in the operating area.

The installation was completed by:

-

A DuroSpan GPS R5 insulating coating on the walls and ceilings, guaranteeing increased thermal resistance,

-

Optimized drainage with an adjusted slope to prevent water accumulation or ice formation,

-

and a digital control panel allowing real-time monitoring via a BMS (building management system) interface.

This system meets ASHRAE 15 , CSA B52 , and EC 2014/68/EU standards for refrigeration safety.

Construction progress

-

Site preparation:

-

Removal of the old equipment.

-

Complete cleaning of internal surfaces.

-

Sanitary protection with temporary films.

-

-

Insulation work:

-

Installation of DuroSpan GPS R5 panels with watertight seals.

-

Application of sealants compatible with food environments.

-

-

Mechanical and electrical installation:

-

Wall mounting of the Bally evaporator.

-

Pulling of insulated copper refrigeration pipes.

-

Installation of the control panel and electrical connection in accordance with CSA Code C22.1.

-

-

Commissioning:

-

Leak test and vacuuming of the circuit.

-

Environmentally friendly refrigerant charge (R-448A, low GWP).

-

Sensor calibration and setpoint verification.

-

Results and Key Performance Indicators (KPIs)

Post-installation measurements demonstrate:

-

Temperature stabilization at 2°C ± 0.3°C ,

-

Energy savings of 24% compared to the old system,

-

35% reduction in defrosting time ,

-

and improved food safety through better temperature uniformity.

In addition, the system is fully compatible with a remote monitoring platform , allowing the manager to be alerted in case of temperature deviation.

Maintenance and monitoring

AirGreen has integrated this installation into its commercial preventive maintenance program :

-

quarterly inspection of drain coils, fans and heating cables,

-

annual verification of operating pressures,

-

Cleaning and disinfection according to MAPAQ protocols.

-

Temperature logs updated for compliance.

A 24/7 SLA also ensures the availability of a refrigeration technician in less than 4 hours in case of emergency.

Compliance, safety and hygiene

All work was carried out according to:

-

MAPAQ requirements for cold storage facilities intended for food,

-

ASHRAE/CSA regulations for commercial refrigeration,

-

and the CNESST guidelines concerning work in confined environments.

The sealing products, insulation and sheaths used are VOC-free and food-grade certified .

Subsidies and return on investment

The project was eligible for Hydro-Québec's Energy Efficiency Program for high-performance refrigeration systems, covering up to 25% of the project cost .

Thanks to the reduction of heat losses and the optimized consumption of the compressor , the estimated ROI is 3.5 years , while ensuring the conformity and sustainability of the system for more than 15 years.

Conclusion

This project perfectly illustrates AirGreen 's expertise in commercial and industrial refrigeration in Montreal, Laval, Longueuil, on the North Shore and the South Shore.

Our interventions combine precision engineering , food safety , and measurable energy performance — essential assets for companies processing and storing temperature-sensitive products.