A critical mandate for business continuity and energy performance

At AirGreen , we were called in urgently by the manager of a logistics warehouse in Montreal East after a breakdown was detected on a ducted air handling unit serving the main storage area.

The challenge: to avoid any interruption of the supply chain by ensuring a rapid, compliant and sustainable recommissioning of the heating, ventilation and air conditioning system.

Site context

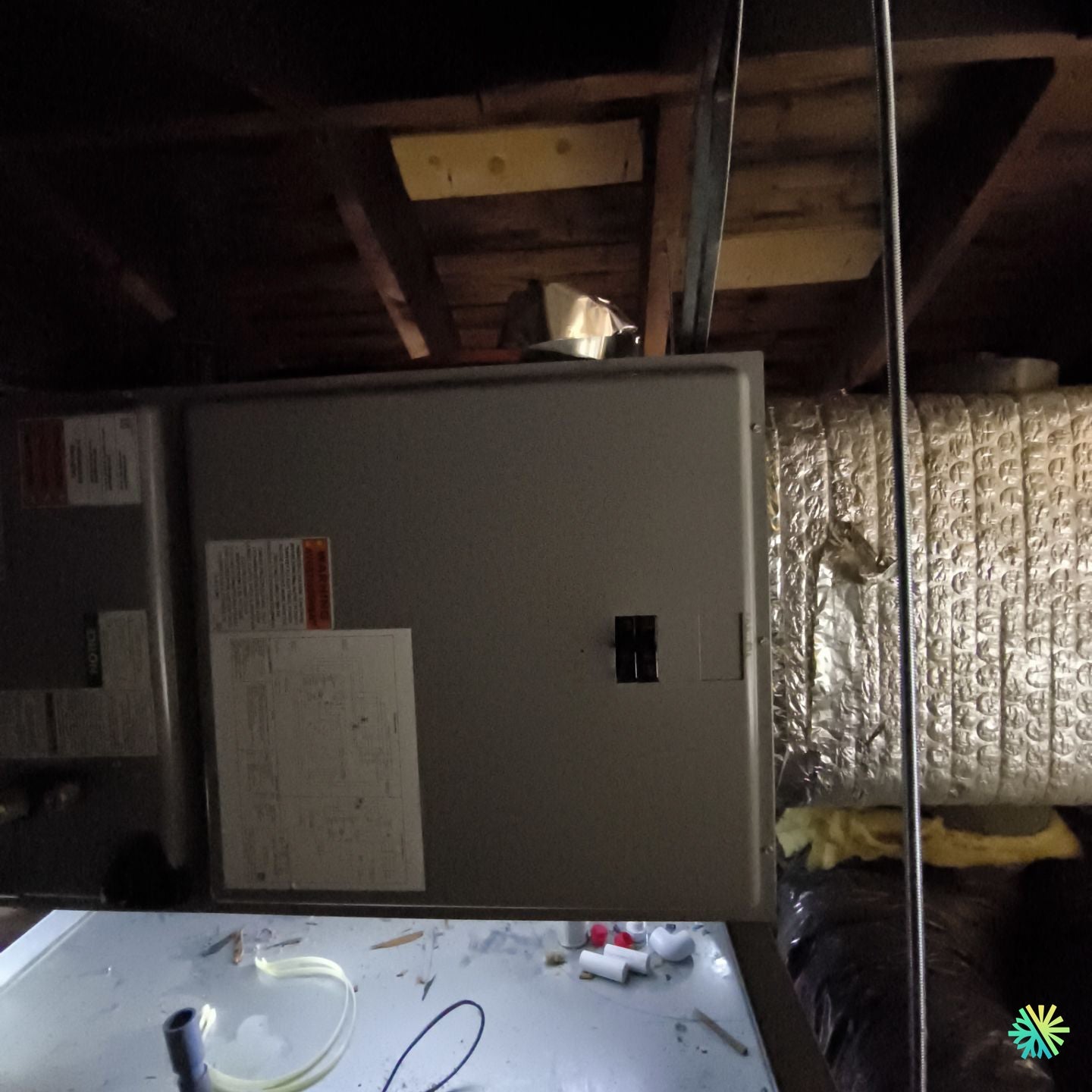

The warehouse, with an area of approximately 1200 m² , houses products sensitive to variations in temperature and humidity. The HVAC system, installed more than eight years ago, is based on a central ducted unit connected to a network of insulated flexible ducts .

Over time, the combination of dust, condensation, and mechanical vibrations had degraded the system's efficiency:

-

significant air leaks at certain joints;

-

static pressure loss in distant sections;

-

degradation of the blowing flow rate , affecting thermal regulation;

-

Torn insulation , causing energy loss and cold air infiltration.

These conditions resulted in increased electricity consumption and unstable internal temperature , potentially compromising the preservation of goods.

In-depth technical diagnosis

Our technicians performed a complete inspection of the HVAC system using a thermal flow meter and a differential pressure gauge to measure static pressure.

The diagnosis revealed:

-

a major leak at the interface of the flexible sheath and the main plenum ;

-

an incorrect inclination of the condensate drainage box ;

-

a loose connection at the electrical control box;

-

a partial misalignment of the main shaft due to a sagging of the wooden structure of the ceiling.

We also confirmed that the unit's blower motor — a commercial 3.5-ton Carrier ducted model — was operating normally, but with a 14% overconsumption related to pressure loss in the ducts.

Technical solution deployed

To ensure a complete and lasting recovery, our AirGreen team implemented a three-pronged solution: mechanical, aerodynamic and energy-related.

1. Repair and realignment of conduits

-

Complete disconnection of damaged sheath sections.

-

Installation of new galvanized anchor collars and joints sealed with HVAC polymer mastic .

-

Replacement of insulated flexible ducts (R-8, aluminized vapor barrier).

-

Balanced replenishment of storage and receiving areas.

2. Repair of the drainage and caisson

-

Complete cleaning of the condensate tray and replacement of the PVC drain pipe .

-

Application of antimicrobial treatment and verification of the gravity slope to avoid any reflux.

-

Sealing the drain line penetration using a waterproof insulation.

3. Electrical verification and calibration

-

Checking the low voltage control circuit (24 V) and tightening the main terminals.

-

Measuring the motor's inrush current to confirm its CSA compliance.

-

Calibration of the wall thermostat and the air return probe .

Construction progress

The work was carried out in a full day (8 hours of continuous intervention) , in a constrained and partially inaccessible environment.

Thanks to our rigorous planning and the use of low-noise portable equipment, we were able to:

-

intervene without interrupting logistical operations ;

-

guarantee a noise level below 65 dB(A) during the repair;

-

maintain a temporary airflow using a portable N+1 fan.

All interventions were carried out under the direct supervision of an RBQ certified AirGreen team leader , in accordance with CSA C22 and ASHRAE 90.1 standards.

Results and Key Performance Indicators (KPIs)

Following the recommissioning and final testing, the results were measured as follows:

-

22% reduction in the unit's energy consumption.

-

Thermal stabilization to ±1.5 °C in all areas.

-

Complete elimination of unwanted air leaks and condensation.

-

Static pressure gain of +35% measured at the plenum.

-

Increased level of comfort for handling personnel.

The customer immediately observed a decrease in compressor cycle time , reflecting improved overall system efficiency.

Preventive maintenance and post-intervention follow-up

AirGreen has integrated this installation into its customized commercial maintenance program , which includes:

-

semi-annual inspection of the duct network;

-

internal cleaning and UV-C disinfection;

-

checking electrical tightening and grounding;

-

annual replacement of the MERV 13 filter;

-

Energy monitoring via BMS telemetry (kWh and temperature curves).

This plan helps prevent any performance drift and ensures the longevity of the Carrier system.

Compliance, safety and sustainability

The project meets the following requirements:

-

Quebec Building Code – Chapter VIII (Energy) ;

-

CSA standards C282 and B52 ;

-

ASHRAE Guidelines 62.1 and 90.1 ;

-

Security measures in confined spaces and a complete lockout/tagout plan.

All the materials replaced (insulation, ducts, PVC piping) were recycled according to AirGreen's environmental policy, in compliance with the ISO 14001 standard.

Return on investment and outlook

The warehouse manager now benefits from:

-

an estimated annual reduction of $1400 in energy costs;

-

of an improved carbon footprint thanks to the reduction of heat losses;

-

improved durability of the blower motor , reducing emergency service calls.

The return on investment is estimated at 2.4 years , supported by an energy performance credit from the Quebec government's EcoPerformance program.

Conclusion

This intervention illustrates AirGreen 's ability to offer robust technical solutions that meet the most stringent commercial requirements.

From fault detection to commissioning, our integrated approach has enabled us to restore performance, reduce consumption and extend the lifespan of the HVAC system in this Montreal warehouse.

AirGreen remains a trusted partner for companies seeking to combine energy performance, safety and business continuity in the greater Montreal area.