Optimizing air quality and energy performance for a high-traffic commercial space

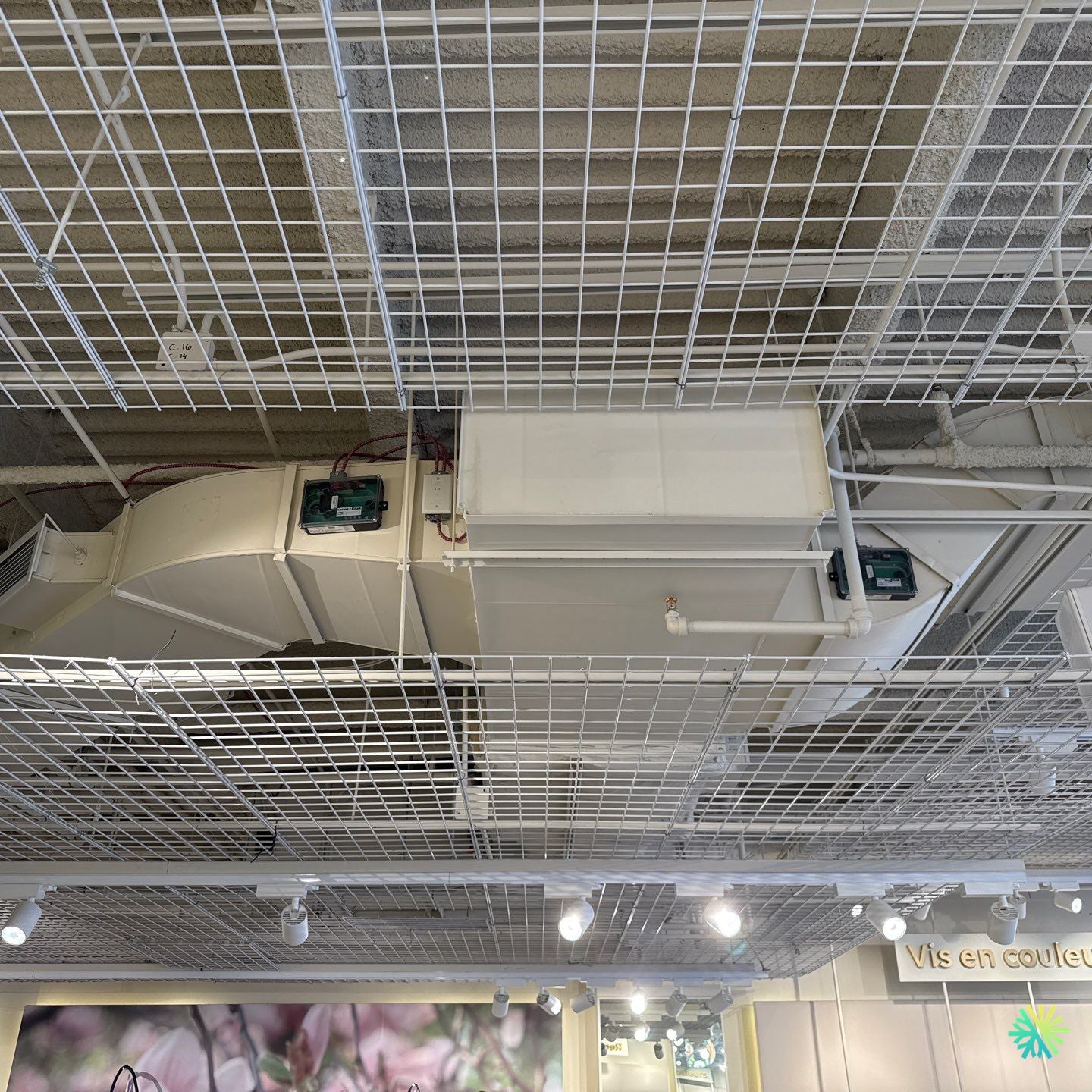

At AirGreen , we recently completed a full retrofit of a centralized ventilation system in a retail store located in downtown Montreal . The goal: to modernize an aging installation without interrupting daily business operations, while achieving measurable gains in energy efficiency and indoor air quality (IAQ) .

This project illustrates our integrated approach to commercial HVAC , where engineering design, operational planning, and regulatory compliance come together to create an optimal indoor environment that is sustainable and compliant with ASHRAE 62.1 and CSA C282 standards.

Project context

The business, specializing in the sale of decorative items, presented several challenges:

-

Outdated ventilation system with poorly insulated ducts and uneven airflow.

-

Unstable thermal comfort causing temperature variations of more than 5°C between zones.

-

Open industrial ceiling making mechanical access complex and limiting space for ducts.

-

Customer requirement: no store closure during the works .

After inspection, our technicians confirmed that the existing air handling units were operating at reduced efficiency, with filters and fans at the end of their useful life.

Technical study and diagnosis

Our HVAC engineers have completed:

-

a complete survey of existing ducts using a portable 3D scanner;

-

static pressure and air flow measurements (balometer and anemometer);

-

an acoustic analysis to assess the noise pollution perceived by customers and employees;

-

a CFD (Computational Fluid Dynamics) model to simulate air distribution in critical areas.

This data enabled a precise diagnosis to be made: the system was only providing 68% of the air exchange rate prescribed by ASHRAE 62.1 , and the main motor's efficiency no longer exceeded 60% of its nominal capacity .

Technical solution deployed

The chosen solution combined mechanical modernization and energy optimization without a complete replacement of the ductwork network.

Key elements of retrofitting:

-

Installation of a Daikin high-pressure ducted ventilation module with variable-speed ECM motor , perfectly suited to open ceilings.

-

Integration of a building automation controller (BMS/BMS) to manage the ventilation speed according to store traffic (CO₂ detection).

-

Added two smart humidity and temperature sensors to balance peripheral and central areas.

-

Partial refurbishment of the main supply duct with internal acoustic lining.

-

Replacing MERV 8 filters with HEPA H13 filters , improving air quality for employees and customers.

Progress of the work

The work was planned in three nighttime phases so as not to disrupt opening hours:

-

Phase 1: Preparation and Locking

-

Securing electrical circuits.

-

Removal of the old motors and sensors.

-

Complete cleaning of accessible ducts.

-

-

Phase 2: Installation of the new Daikin equipment and BMS sensors.

-

Suspended positioning of the ducted module above the existing light fixtures.

-

Connection to the electrical network and the main conduit.

-

-

Phase 3: calibration, balancing and final validation.

-

Adjusting airflow per vent.

-

Verification of blowing pressures and temperatures.

-

Commissioning report delivered to the owner with certified measurements .

-

Results and performance indicators

At the end of the project, the performance achieved exceeded expectations:

-

+32% improvement in fresh air renewal .

-

-22% reduction in electricity consumption thanks to ECM motors.

-

Thermal uniformity of ±1.2 °C across the entire sales floor.

-

Noise reduction of 6 dB(A) in the checkout area.

-

No interruption of business activity.

Employees reported a noticeable improvement in comfort and air quality , with a significant reduction in dust and odors.

Maintenance and operational monitoring

AirGreen has implemented a quarterly preventative maintenance program including:

-

inspection and cleaning of fans and filters,

-

GTB data recording (temperature, humidity, CO₂),

-

calibration of ambient sensors,

-

detailed report automatically sent to the building manager.

A remote monitoring platform now allows the customer to view energy performance and maintenance alerts in real time, promoting predictive rather than corrective maintenance .

Compliance and safety

All interventions were carried out in compliance with the standards:

-

ASHRAE 62.1 – Ventilation for Acceptable Indoor Air Quality

-

CSA B52-21 – Code for Mechanical Refrigeration

-

Quebec Building Code and City of Montreal Municipal Regulations

-

CNESST procedures: lockout/tagout, working at height, intervention perimeter.

An electrical compliance certificate was issued at the end of the project, guaranteeing the safety and reliability of the system.

Subsidies and return on investment

Thanks to the energy performance achieved, the project was eligible for the EcoPerformance program (Transition énergétique Québec), covering 20% of the total cost .

The estimated return on investment is 3.5 years , primarily due to reduced energy consumption and savings on corrective maintenance.

Global impact and sustainable perspective

This project demonstrates that a well-planned HVAC retrofit can transform a commercial space without disrupting operations or compromising interior aesthetics.

Daikin's ECM motor solutions and intelligent BMS management offer fine regulation, adapted to occupancy variations, promoting constant comfort, increased energy efficiency and a reduced carbon footprint .

AirGreen continues to support businesses, shopping centers and distribution chains in the greater Montreal area, Laval, Longueuil, the North Shore and the South Shore , by offering them customized, compliant, reliable and scalable HVAC solutions .