A service call on a roof in Laval: a refrigerant leak detected

At AirGreen , we are often called upon to intervene in demanding technical situations, particularly on installations at height or difficult to access. On that day, our team went to Sainte-Dorothée (Laval) to diagnose a Haier wall-mounted heat pump that was no longer producing enough cold, despite maximum demand on a hot summer day. The owner, concerned about seeing his system lose performance, contacted our technicians for a complete check of the refrigeration circuit .

Diagnosis: Loss of performance due to a refrigerant leak

Upon our arrival, one thing was clear: the indoor unit's blowing temperature was significantly below comfort standards. After checking the pressures using our digital manifold , we observed an insufficient refrigerant charge.

Analysis of the pressure and temperature values quickly pointed us towards a probable leak in the circuit .

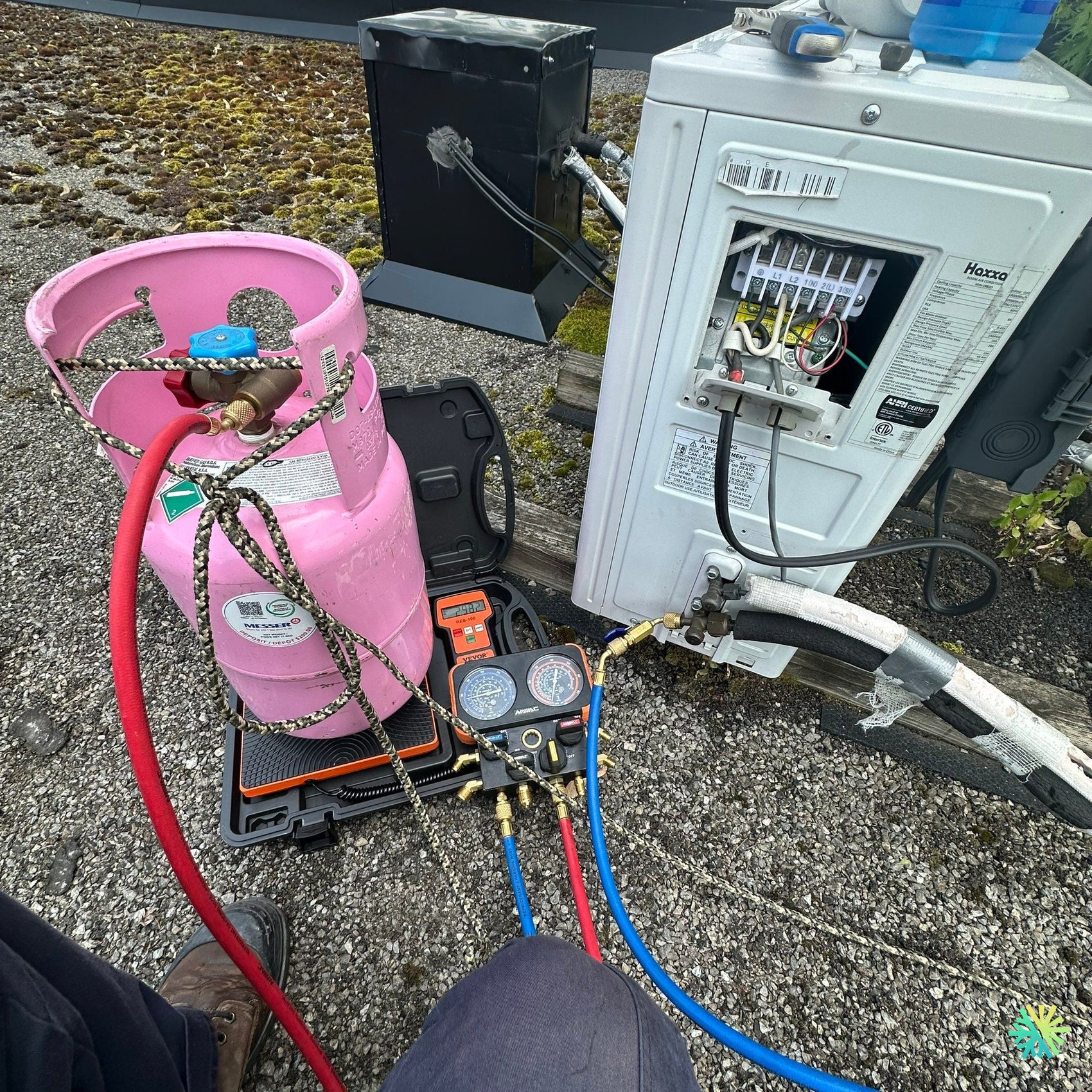

Our technicians then connected a bottle of R-410A refrigerant (recognizable by its pink color) and a set of precision electronic instruments , including a leak detector and a load scale . These tools allowed us to confirm the presence of a microleak on a flare connection of the external compressor.

Step 1: Leak detection and repair

The leak was coming from a slightly under-tightened fitting , located at the junction between the suction pipe and the outdoor unit. After isolating the system and recovering the remaining gas, we:

-

Cleaned the connection area.

-

Tightened and resealed with a new gasket and tightened to the calibrated torque .

-

Performed a nitrogen pressure test at 350 psi to verify perfect sealing.

-

Allow the system to sit under pressure for 30 minutes, with no loss detected.

Once integrity was confirmed, we proceeded to completely evacuate the circuit using a precision vacuum pump until reaching -30 inHg, ensuring the elimination of all traces of humidity.

Step 2: Refrigerant recharge and pressure adjustment

The recharge was carried out using our AirGreen certified R-410A bottle , strictly following the quantity prescribed by the manufacturer Haier, i.e. 1.35 kg for this wall-mounted model.

We used an electronic scale and controlled the dynamic pressures using the manifold to ensure optimal loading, respecting the expected operating conditions.

Final readings confirmed a perfect balance between high and low pressure , with stable subcooling and superheat within specifications.

Step 3: Performance verification and return to service

After the complete readjustment, we started the heat pump to validate the overall performance :

-

Measured blown air temperature: 8°C.

-

Ambient air temperature: 25°C.

-

Temperature differential (ΔT): 17°C — a sign of optimal performance.

We also carried out an electrical check inside the outdoor unit's connection box to verify the integrity of the cables, connections and internal circuit breaker. No signs of oxidation or overheating were found.

Result: restored comfort and maximum efficiency

Once the repair was complete, the customer immediately noticed the difference. His Haier wall-mounted heat pump was back to its original efficiency, providing fast and stable cooling throughout the house.

Our intervention not only made it possible to correct the leak and avoid excess energy consumption , but also to extend the life of the compressor by ensuring balanced and constant pressure in the circuit.

AirGreen Recommendations: Prevention and Regular Maintenance

To prevent this type of problem from recurring, we recommended annual preventative maintenance to the customer, including:

-

Cleaning the coils and filters .

-

Checking pressures and temperatures .

-

Checking the connections and the refrigeration insulation .

-

Inspection of the electronic board and the condensation drain .

These simple but essential steps help prevent yield losses , avoid minor leaks, and ensure reliable and economical operation throughout the year.

Conclusion: expertise and rigor signed AirGreen

This type of intervention perfectly illustrates the rigor and precision that make AirGreen's reputation in the field of HVAC service in Montreal, Laval and on both shores .

Our certified technicians work on all major brands— Haier, Fujitsu, Midea, Gree, Lennox, Goodman, Zephyr , and many others—with calibrated tools and proven methods .

Every service call is an opportunity for us to ensure performance, reliability and peace of mind for our customers.

And as always: AirGreen, your trusted partner for sustainable comfort.